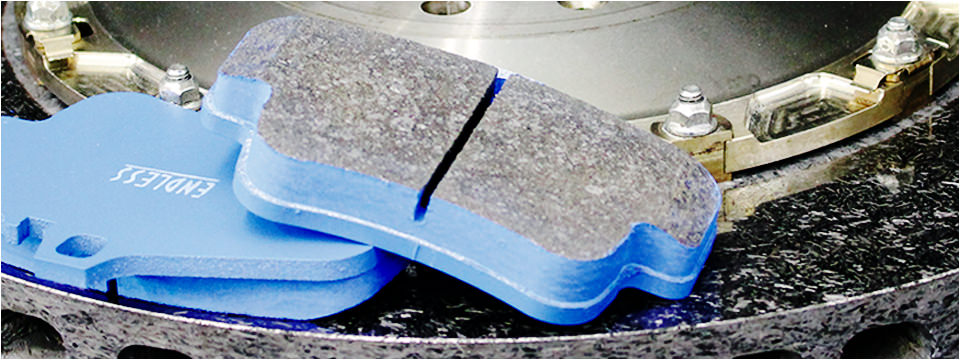

Brake Pad for Ceramic Carbon Disc

In recent years, an increasing number of sports cars have been coming equipped with Carbon Ceramic Discs from the factory. Applications such as the Porsche PCCB (Porsche Ceramic Composite Brake), the Ferrari CCM (Carbon Ceramic Matrix) and the Nissan GT-R Spec-V NCCB (Nissan Carbon Ceramic Brake) are increasingly being more widely adopted as standard options. In addition to the reduced unsprung weight, the Ceramic Rotors offer stable braking performance and exponentially increased bite. While these rotors offer increased performance, they do come with drawbacks such as increased wear of the rotors and OEM brake pads as a result of increased heat caused by the higher initial bite these brakes tend to offer. Due to the high costs associated with replacing rotors, many drivers tend to replace them with heavier cast iron rotors for circuit use. In response to these issues ENDLESS began development on a specialized line of brake pads in 2003 and after six years of development and testing completed two specialized compounds which demonstrate high-level performance even when used at the track. The W007 and W008 for track and street use respectively were born.

CARBON CERAMIC ROTOR COMPOUNDS

W007 (Semi Metallic; Carbon Ceramic Rotor pads)

Circuit use only. Designed specifically for use with Brembo S.G.L CCM (Carbon Ceramic Matrix), Porsche PCCB, and Nissan GT-R Spec V (NCCB) disks. This brake compound has really good heat resistance and is very kind towards Carbon Ceramic disks. Development and testing was done on the Nurburgring circuit. Thermo-paint is definitely recommended for the brake rotors as this brake pad has really good heat resistance to match the heat capacity of CCM Rotors.

W008 (Semi Metallic; Carbon Ceramic Rotor pads)

OEM Brake pads for the Brembo S.G.L CCM, Porsche PCCB, Nissan NCCB system have been deemed to have certain weak points in pad wear, and temperature resistance. The W008 was born from the W007, and can be used for street, and circuit use. This pad has good heat resistance, pad wear, anti-fade characteristics, and pedal feeling. This pad requires the use of OEM anti-noise shims on the Nurburgring circuit. Thermo-paint is definitely recommended for the brake rotors as this brake pad has really good heat resistance to match the heat capacity of CCM Rotors.