Racing Mono6 GT CMC

Front Monobloc Caliper for CMC Rotor

Racing Mono6 GT CMC

Racing Mono6 GT CMC

RacingMONO6GT was developed targeting GT race cars in Japan and overseas. By combining these technologies, such as computer-based strength / rigidity analysis, selection of optimum materials, and state-of-the-art forging method, RacingMONO6GT is lightweight yet has the highest level of rigidity, and its performance has been race tested and proven.

Fielded in the Nissan GT-R NISMO GT3, The RacingMONO6GT has been race tested and proven helping lead teams to multiple wins. In addition, the 2018 model has introduced the latest topology optimization technology to further improve performance.

Specs

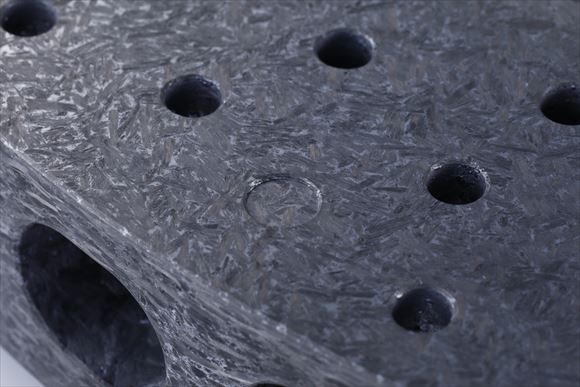

Ceramic Carbon Brake Rotor

CMC (Ceramic Matrix Composites) brake rotor. Since carbon fiber is reinforced with ceramic and molded, it is lightweight and offers excellent heat resistance and durability. The primary issues with current carbon rotors is that temperature control is difficult, but the newly developed CMC brake rotor demonstrates high performance under conditions ranging from street driving to circuit driving.

The genuine front brake rotor used in the NISSAN R35 GT-R (NISMO) weighs approximately 11.4kg and the rear rotor 11.94kg, while the front CMC (Ceramic Matrix Composites) rotor used in this kit weighs 7.76 kg and the rear rotor weighs 8.66 kg. A weight savings of 3 kg or more per disc.

-Stainless steel is used for the bell housing in consideration of heat resistance.

-Emphasis is placed on initial bite and braking feedback. The diameter and number of drilled holes have been optimized for the front rotor (left) and rear rotor (right).

Brake Pads Suitable for Ceramic Carbon Rotors

This brake system comes with ceramic rotor specific brake pads, with two types of brake pads available to choose from either for street or circuit use.

Bedding

In order to bring out the optimal performance of the circuit-dedicated pads, which emphasize high-temperature use characteristics, it is extremely important to perform the recommended bedding procedure during which heat is graddually applied in advance before hard driving. Brake pad bedding is always completed in the top racing categories to ensure the best performance possible from the brake pads. Before using semi-metal brake pads, proper bedding is required to stabilize high temperature performance and extend the life of the pads and rotors.

[Bedding Procedure]

When driving on a circuit with a new set of brake pads installed, gradually raise the rotor temperature to about 400 to 500 ° C while avoiding heavy braking and hard stops. After that, allow the rotors to gradually cool down to 100 ° C.

* It may not be possible to bring out the optimal performance of the brake pads when bedding in the rain or with exceedingly cold ambient temperatures. Bedding should be done in fine weather if at all possible.